Manufacturers in the jewelry packaging boxes on technology with uv, hot stamping, four color printing, color printing, laser, hit convex, etc, but there's hot stamping are generally jewelry packaging boxes factory first recommendation, because his metallic color for consumers to have the feeling of a kind of high-tech, so hot stamping often is favored by merchants from all walks of life, but how to discern the stand or fall of hot stamping process?Today I will share 3 tips with you.

First, we need to know the jewelry packaging boxes factory they hot stamping technology is going on, is actually moving electrochemical aluminum foil by pressurization on paper, so the first method is to observe paper box manufacturers call the appearance of the aluminum foil, a roll of healthy qualified electrochemical aluminum foil, he the surface layer of metal surface reflective performance is excellent, cutting out a small piece or private, is able to reflect the reflection of light, more like the ancient ancient bronze mirror, and very smooth, but a roll of unhealthy electrochemical aluminum foil,His color seems to be relatively dull. This dullness is not due to the dullness of matte gold, but because the surface treatment is not good, and the reflection of light is not synchronous, so observation can also play a certain screening effect.

The second method is pulled off a small piece of electrochemical aluminum foil, spread on a blank sheet of paper, and then use scratching nails for operation, this is the effect of the hot stamping simulation, this process is mainly observed two points, one is the scraping strength and the effect of aluminum foil old weak is passed on to the paper, the relationship between the two is proportional to, gently scraping the metallic effect on the electrochemical aluminum foil will be passed on to the paper, just not stable, may not be strong with the force, the greater the effect becomes more reliable this is the relationship between the two, if you use the effect of hot stamping machine is very standardization can also see, hot stamping effect often has a concave down,Is this reason, to make the effect is firm, then hot stamping force to be strong enough, and the general force, also enough to the cardboard down, and like the manual operation, is only used to verify the electrochemical aluminum foil, that is, hot stamping material is not one of the methods of high quality.

The third method is to select several ironing effect packaging cartons in the sample room of jewelry packaging boxes manufacturer, but with the following conditions: (1) has the appearance of fine lines.

(2) large area full version stamping.

(3). The hot stamping color diversity, type will be found in the two in front of the fine lines is often fall off the worst-hit areas, tipping is a common thing, but a tiny grain loss is the most likely to happen, so take a look at these fine lines have fall off phenomenon, and large area full version of the hot stamping, is hot stamping version of the test, to jewelry packaging boxes of the potential development of a mechanical strength measure standard, the full version of hot stamping is not so much the carton factory can make,And the third item of diversity mainly reflects the hot stamping color reserves of jewelry boxes manufacturers, bright gold, dumb gold, bright silver and dumb silver are inevitable, and the more colors, the stronger the strength.

|

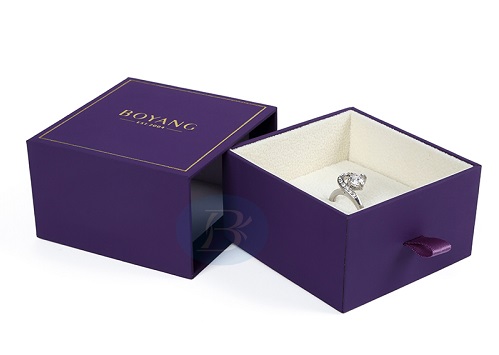

It's March 2019, and what will it be like for the jewelry packaging industry?As for the development status of jewelry packaging industry and the development trend of jewelry packaging industry, it is certainly full of development opportunities and challenges. Today, Boyang, who has more than 10 years of jewellery box manufacturers experience, has made a profound analysis of the development prospect and trend of jewelry packaging industry. Jewelry packaging industry is mainly divided into two aspects: on the one hand, jewelry box packaging box, on the other hand, jewelry props tray, jewelry packaging and jewelry display. As a whole, it is a labor-intensive industry, which requires a large number of labor to operate, and the cost is relatively high.However, if jewellery box manufacturers take the branding route, improve the quality of jewelry packaging products and production efficiency, and strictly follow the set process, they can also make good achievements. ...

评论

发表评论